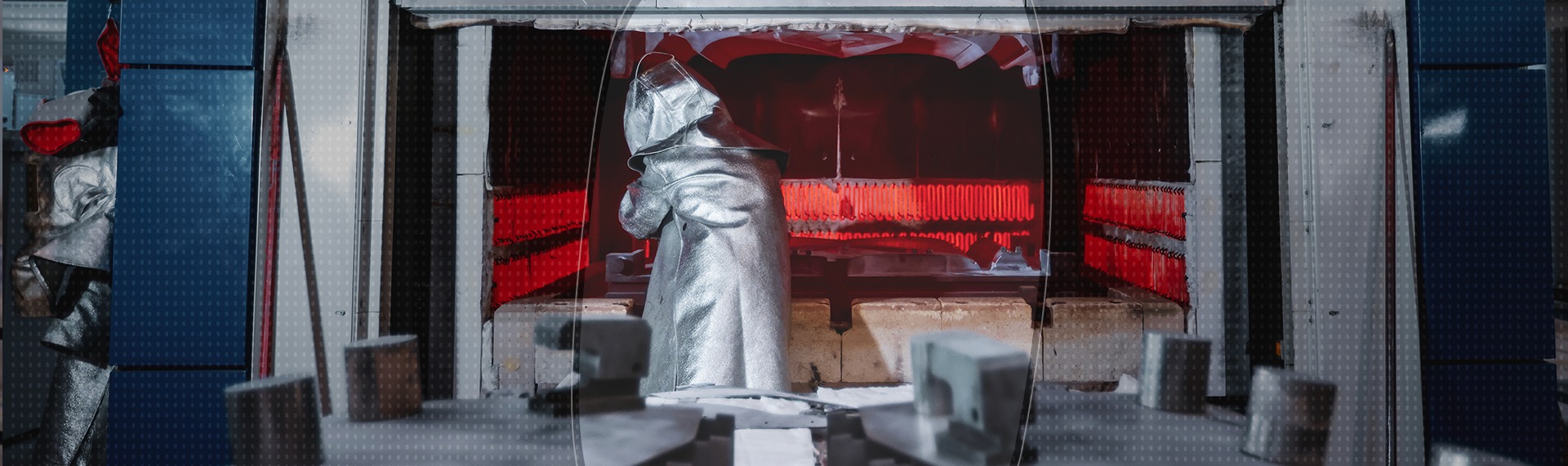

The LAUAK Group is equipped since 2018 with several Hot Forming (HF) and Superplastic Forming (SPF) presses with Maximum strength 800 T and platen size up to 1.8mx1.5m. This technology allows the production of titanium parts with complex shapes that require significant elongations and guarantee very high mechanical performances for an optimized final weight.

MEENS

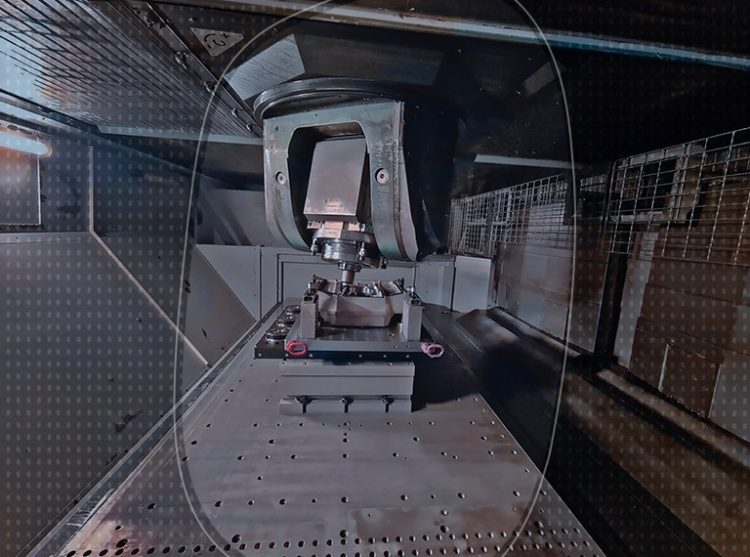

- 2-axes and 5-axes lasers trimming machine

- 3 presses capable for HF* and SPF**

- Tool preheating oven

- Counterskin cobots

PROCESS

- Laser trimming

- Hot Forming*

- Superplastic Forming**

⎯ From 650° to 940°

⎯ Up to 800 tons max press capacity

⎯Up to 1800 x 1500mm platen capacity

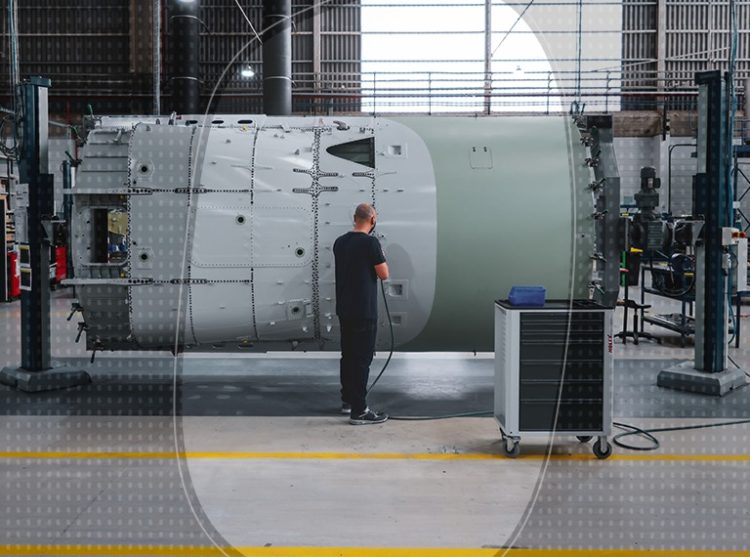

- Sub-assembling/Fastener installations

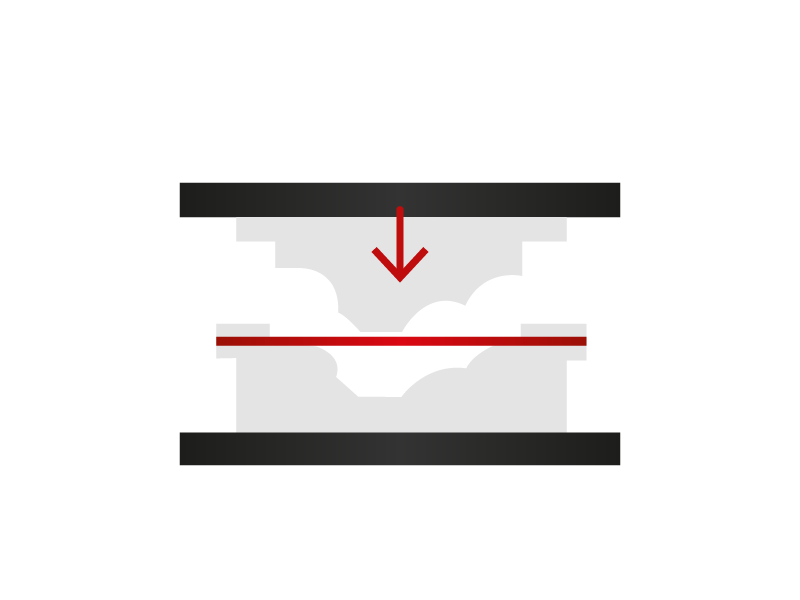

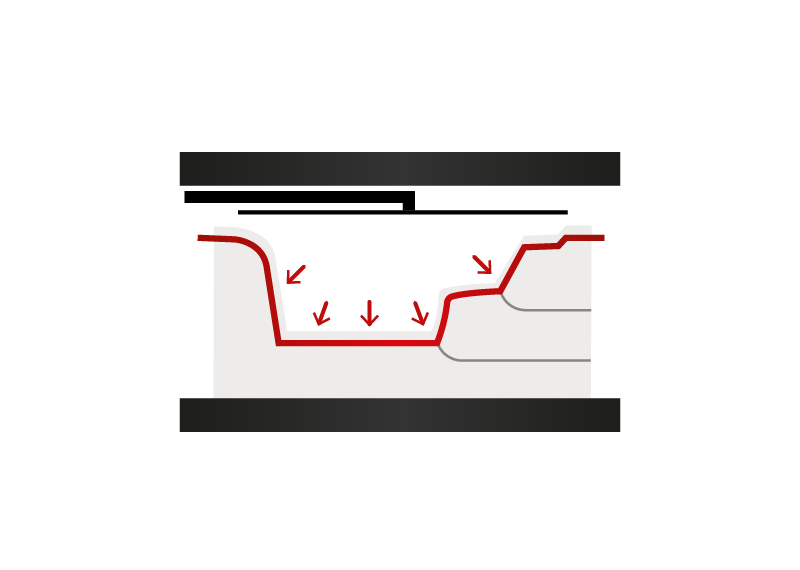

HF (Hot Forming)*

Deformation by punch/die tooling

allowing elongations up to 50%

SPF (Superplastic Forming)*

Deformation by dies and stamping

by gas punch (Argon intert gas)

allowing elongations up to 500%

PRODUCTS

Waste water

service pannel

A350

AIRBUS

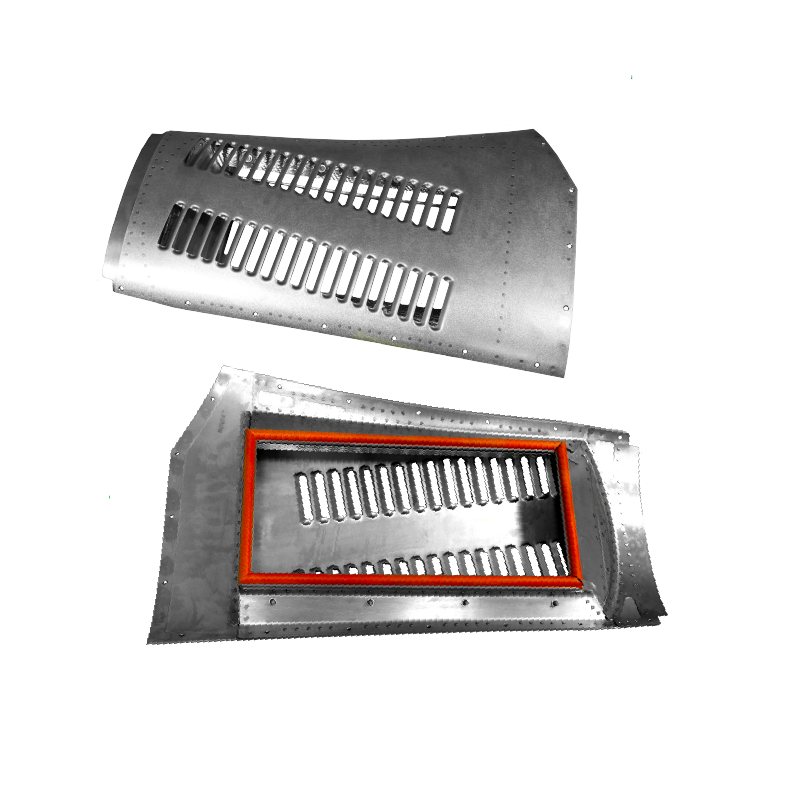

Heat exchanger cover

A320

AIRBUS

Exhaust duct precooler

G280

IAI

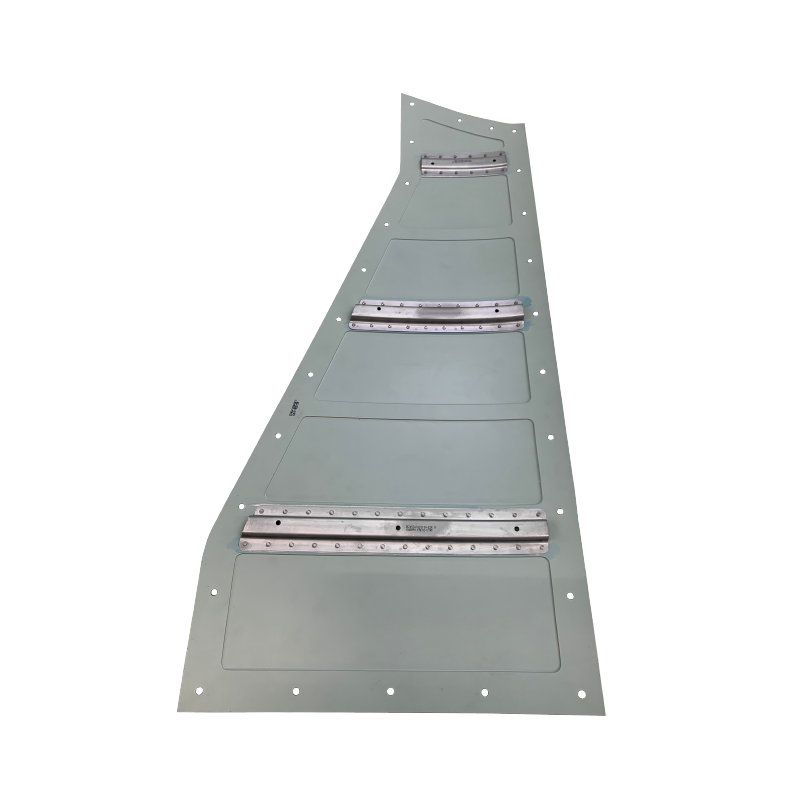

Skin upper assy

A320

AIRBUS

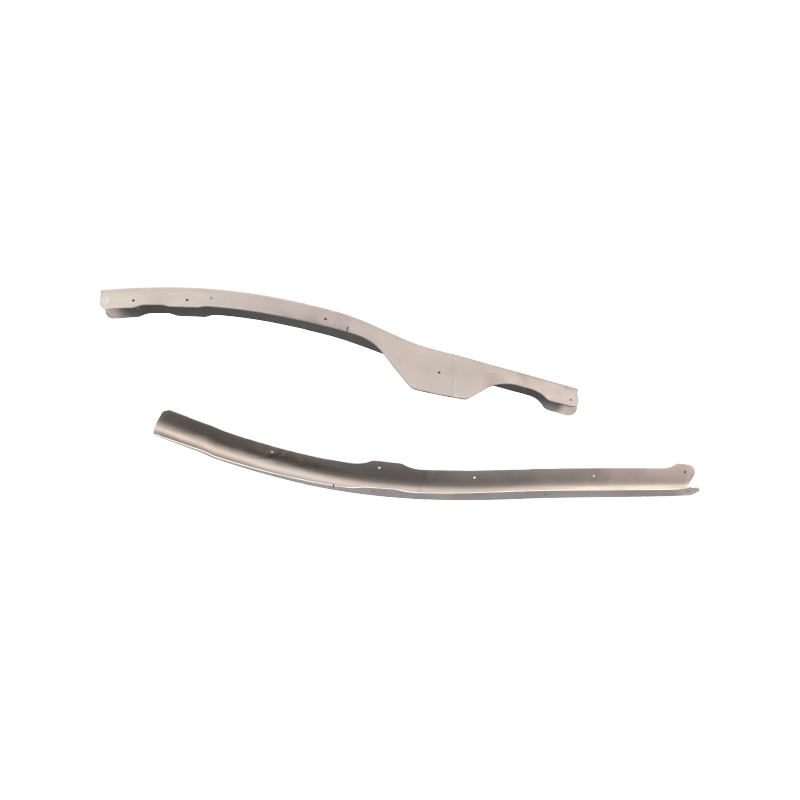

Lower corner

A320

AIRBUS

Fairing oil sump bearing 3

M88

SAFRAN AICRAFT ENGINES

Upper corner

A320

AIRBUS