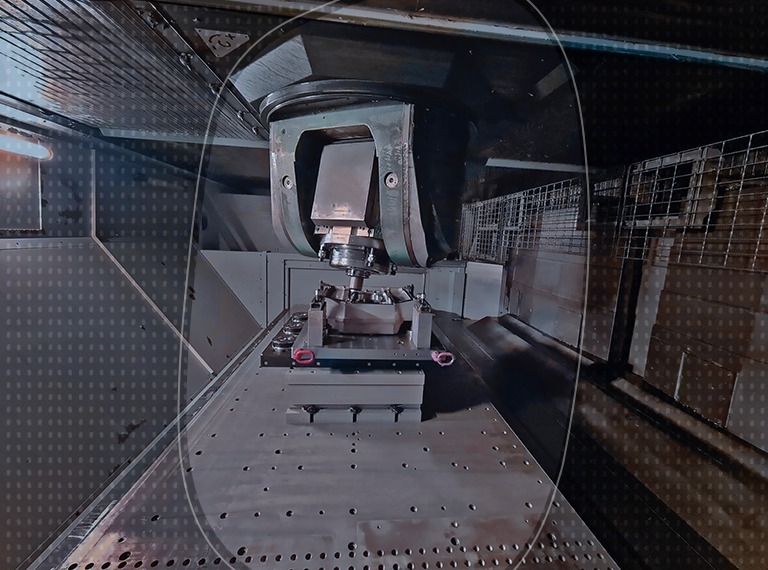

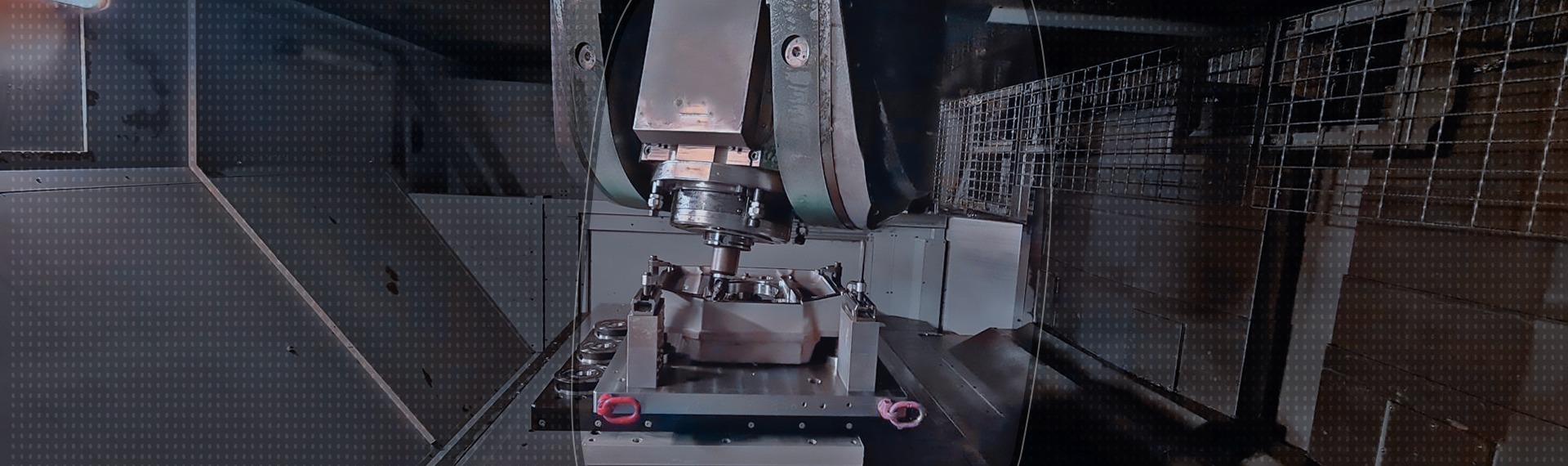

The LAUAK Group uses more than 40 digitally-controlled machines to manufacture machined basic parts and sub-assemblies.

On each development segment, the Lauak Group endeavours to offer a local development solution to its customers and best cost solutions in terms of production.

MEANS

- 40 machining centers from 3 to 5 axes small and large dimensions (up to 4m)

- Combined Lathe-Milling centers (horizontal and vertical, 5-axes)

- Milling centers with automatized Pallet-Changing

- Shot peening machines

- Three-dimensional measuring machines

- Scan box

- Penetrant testing lines

- Surface treatment and Painting lines

PROCESS

- Turning

- Milling

- Prestressing shot peening

- Dimension measurement and scanning

- Non-destructive testing (dye penetrant inspection)

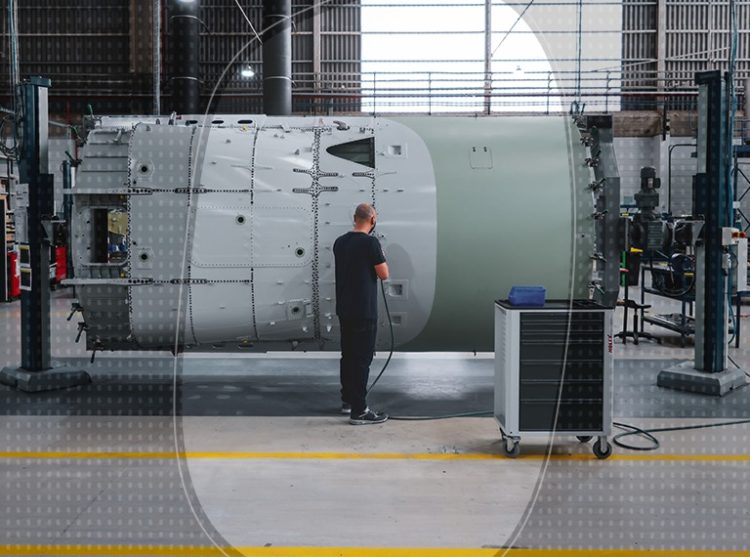

- Bearing installation

- Assembly

- Surface treatment and painting

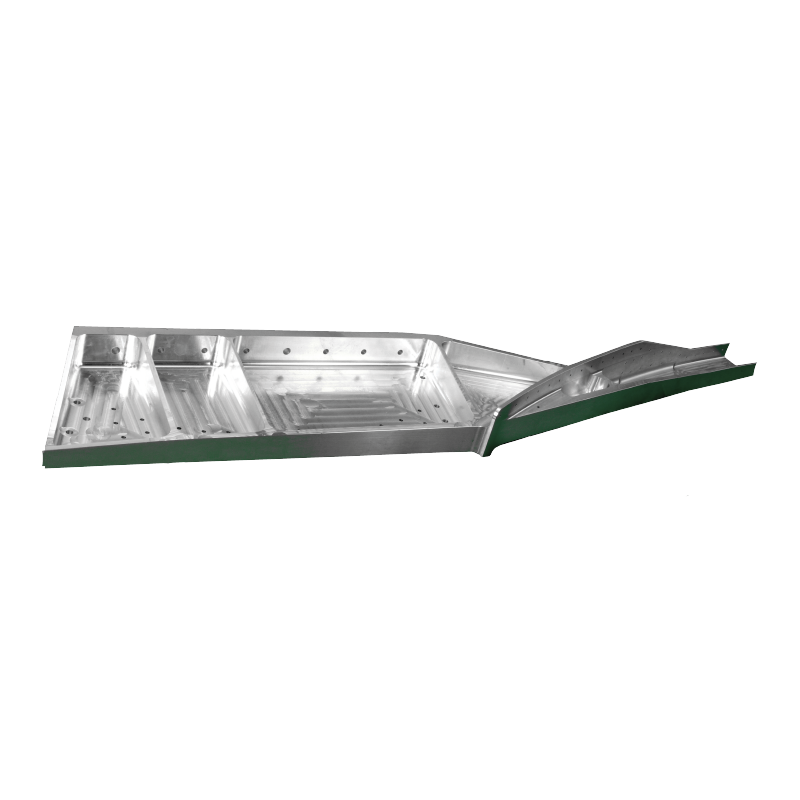

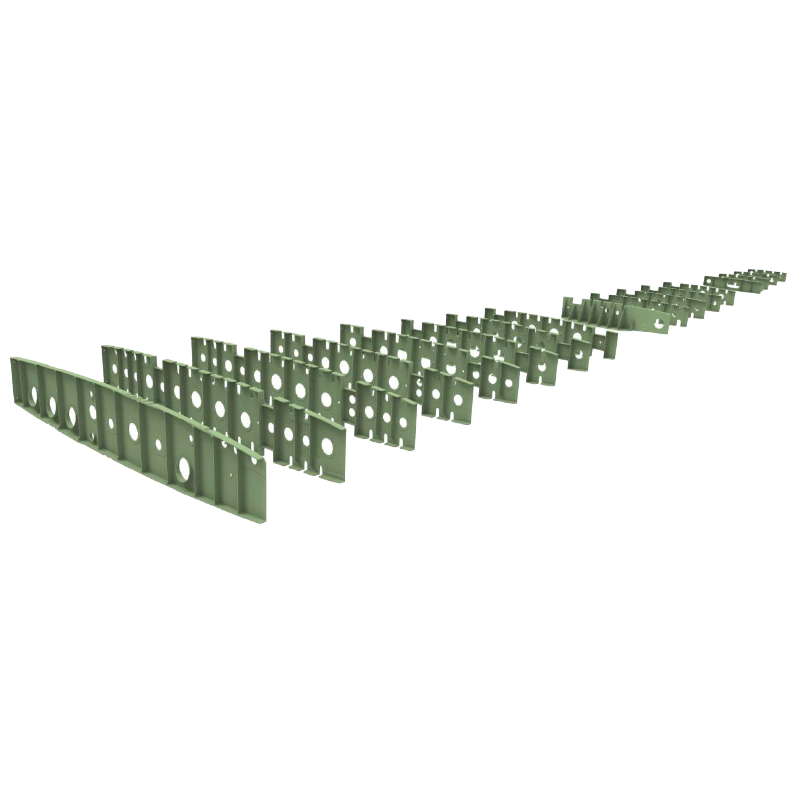

PRODUCTS

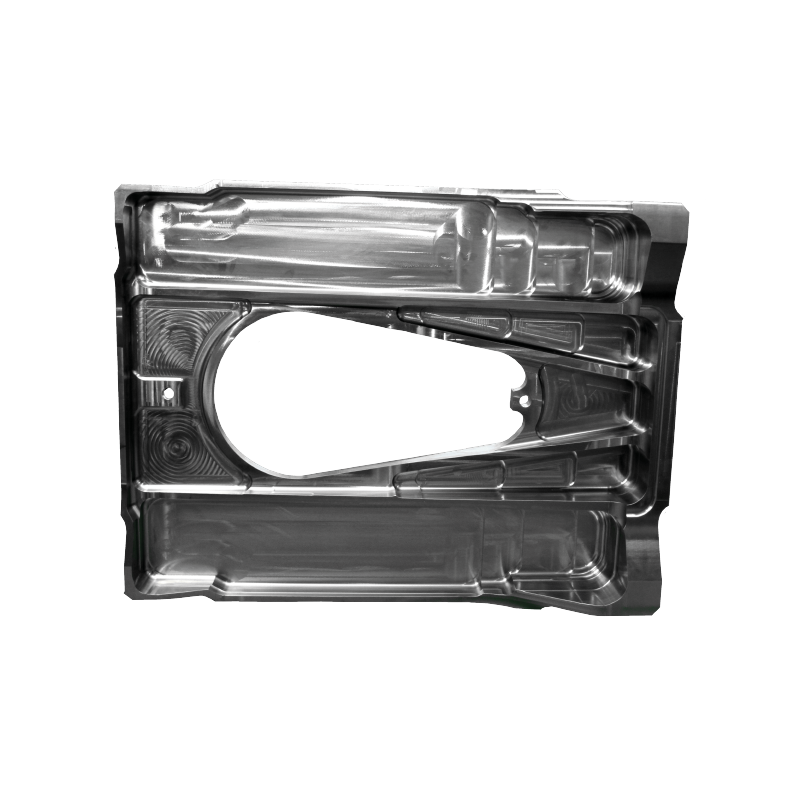

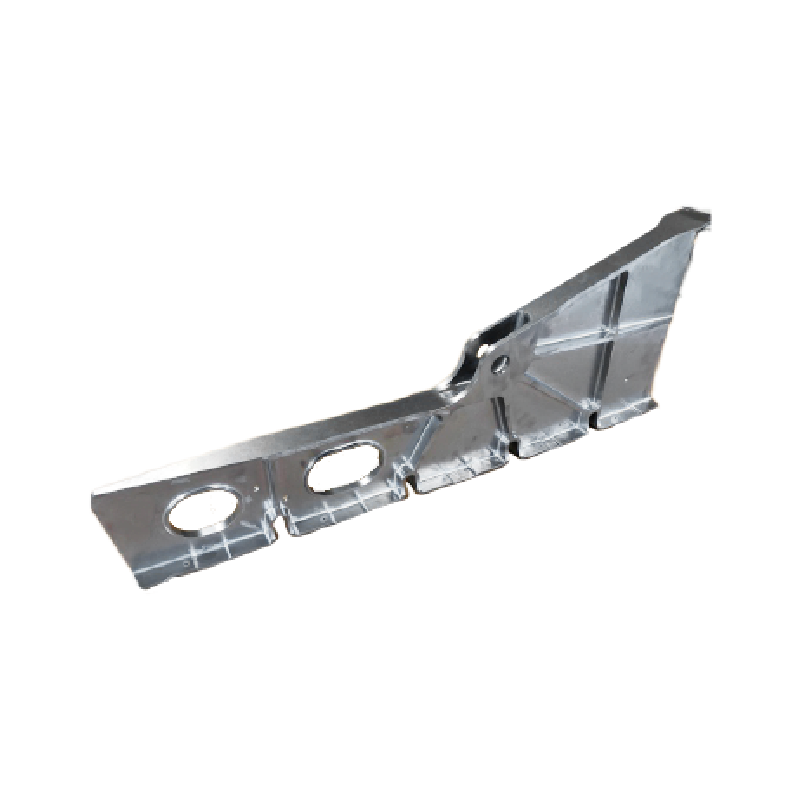

RIB 8 et 9

A350

AIRBUS

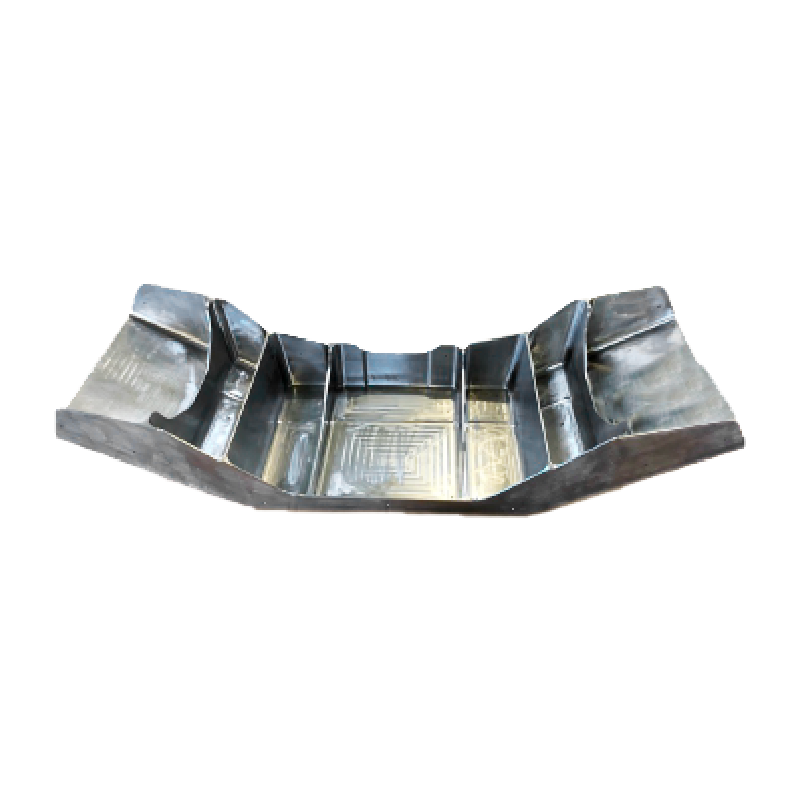

Rib 5

E2 -170/190

EMBRAER

Fitting actuator

KC390

EMBRAER

Spar 1

KC390

EMBRAER

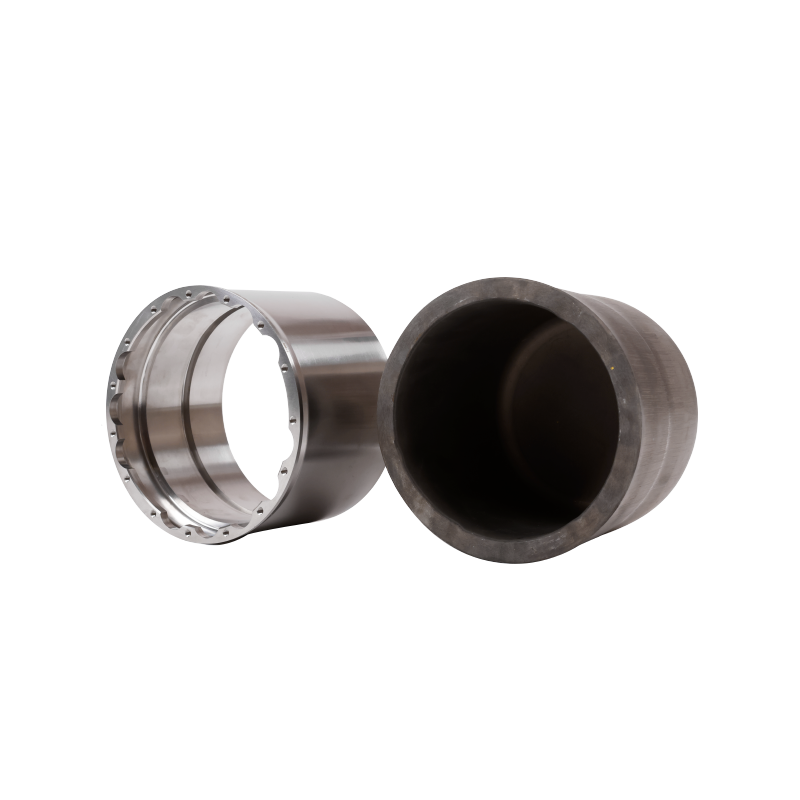

Retention turbine

AW189

SAFRAN POWER UNITS

Compressor vein

AW189

SAFRAN POWER UNITS

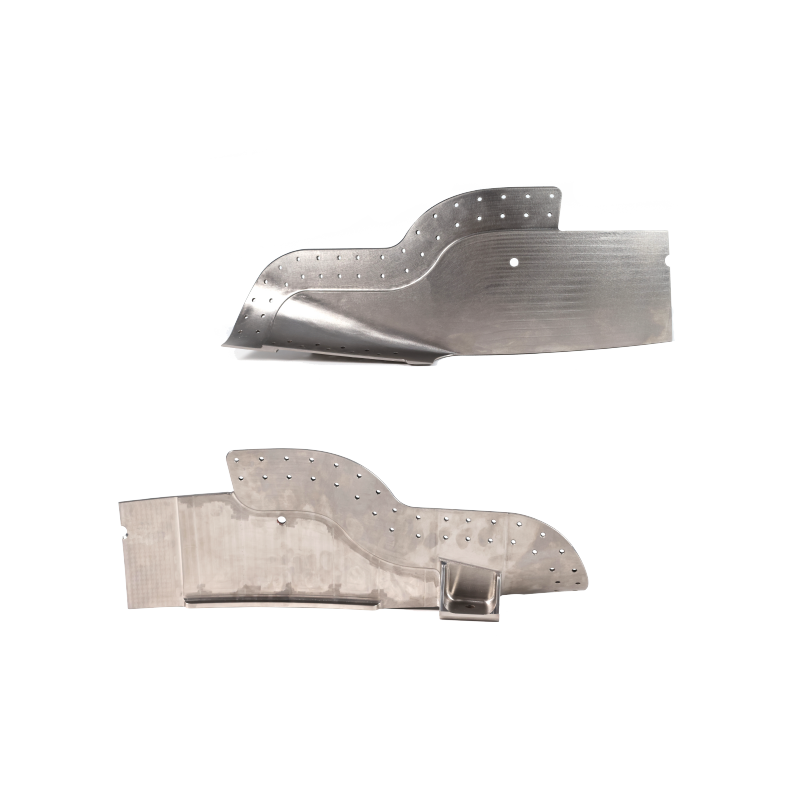

AFT close out fitting

Boeing 737

SPIRIT

Forging frame

F2000

DASSAULT AVIATION

Ribs

F6X

DASSAULT AVIATION