The historical activity of the LAUAK Group, we are specialists of aeronautical panel and sheet metal working, both simple or complex, and with all types of materials, from aluminium alloys to hard metals (stainless steel, Inconel, titanium).

MEANS

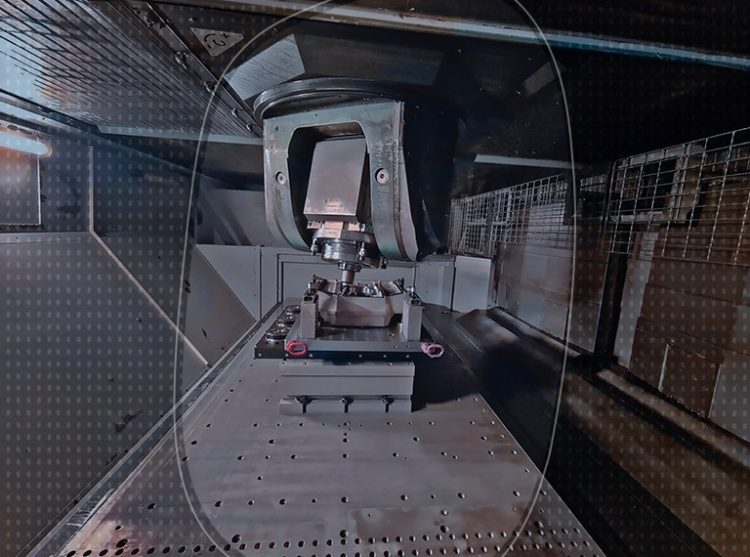

- 2-axes laser punching and trimming machines

- 5-axes laser trimming machines

- Folding/Rolling machines

- Sandblaster/Shot peening machines

- Hand forming traditional equipments

- Heat-tratment furnaces of aluminum

- Double and triple-action stamping presses

- Ruber presses 200 bars

- High-pressure fluid cell presses 800 bars

- TIG, MIG, Laser, Seams, Spot welding stations

- Automatized digital and analog radiography cabins

- Penetrant testing lines

- Surface treatment lines (TSA, CAA, Passivation, CCC, Pickling, Degresing)

- Paint cabins

PROCESS

- Laser and Machining Trimming/Punching

- Aluminum Heat treatment

- Stamping/Pressing/Folding/Rolling

- Cold forming

- Hand, Automatized and Orbital welding

- Non-destructive testing (X-ray, dye penetrant inspection)

- Surface treatment and painting

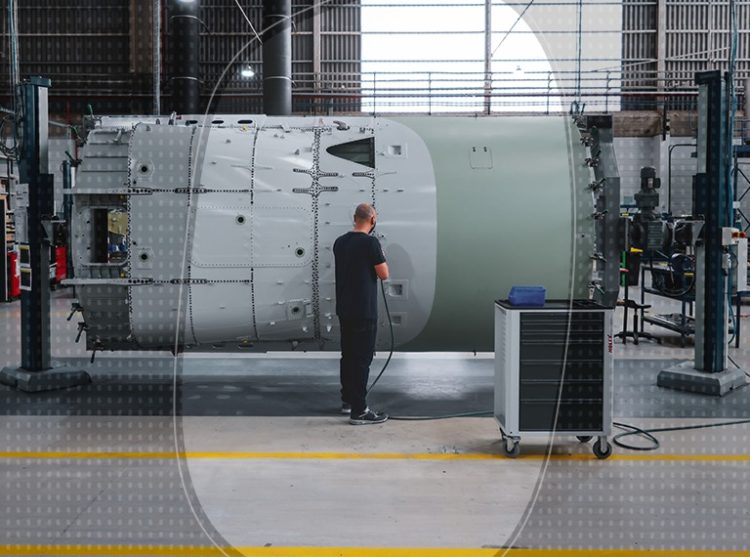

- Sub-assembling/Fastener installations

PRODUCTS

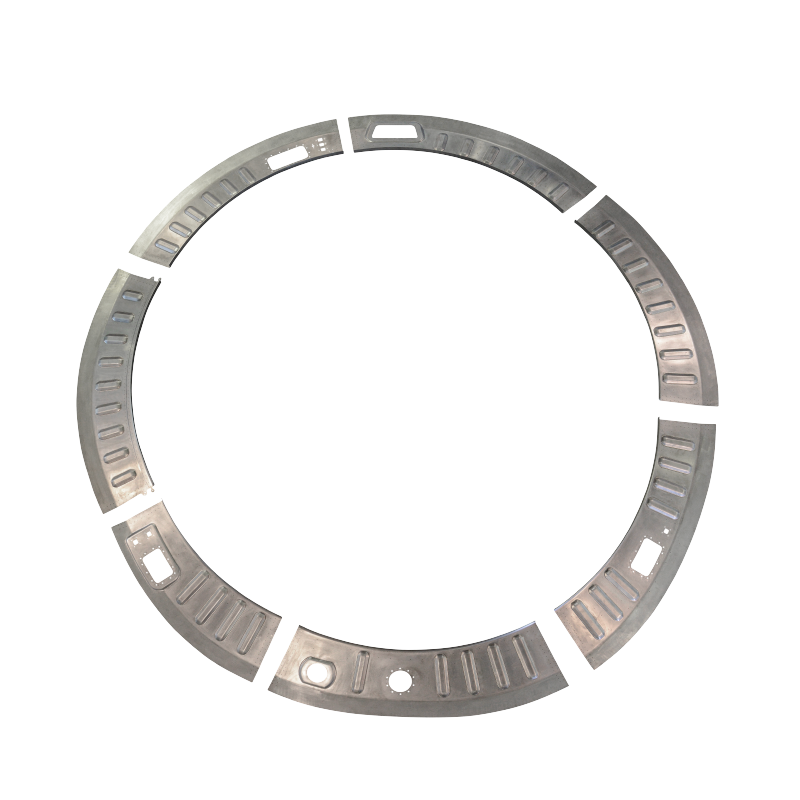

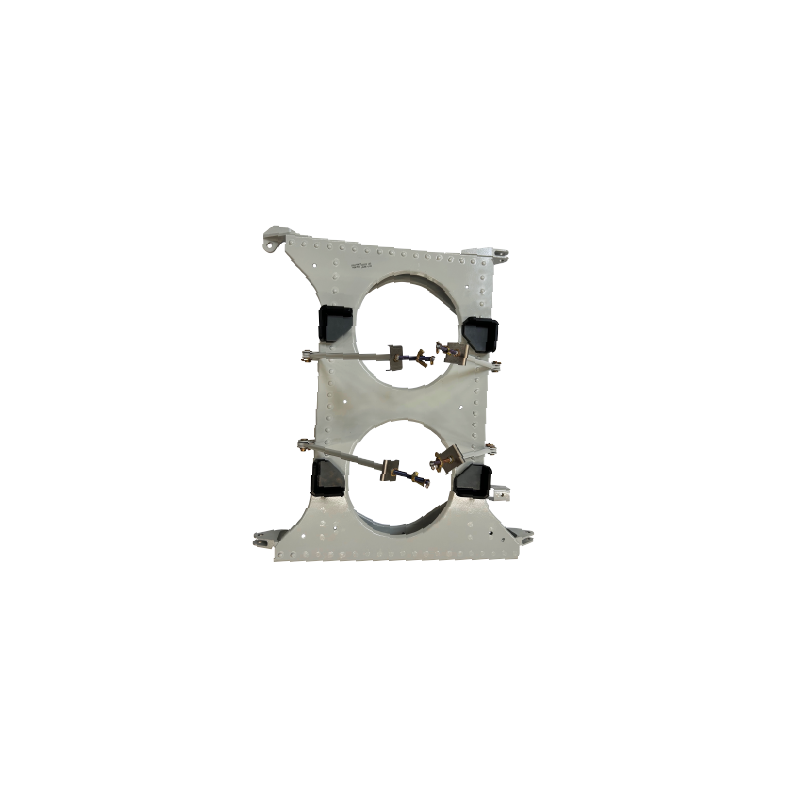

Bulkhead frame

A330

AIRBUS

Tail Cone

PRAETOR

EMBRAER

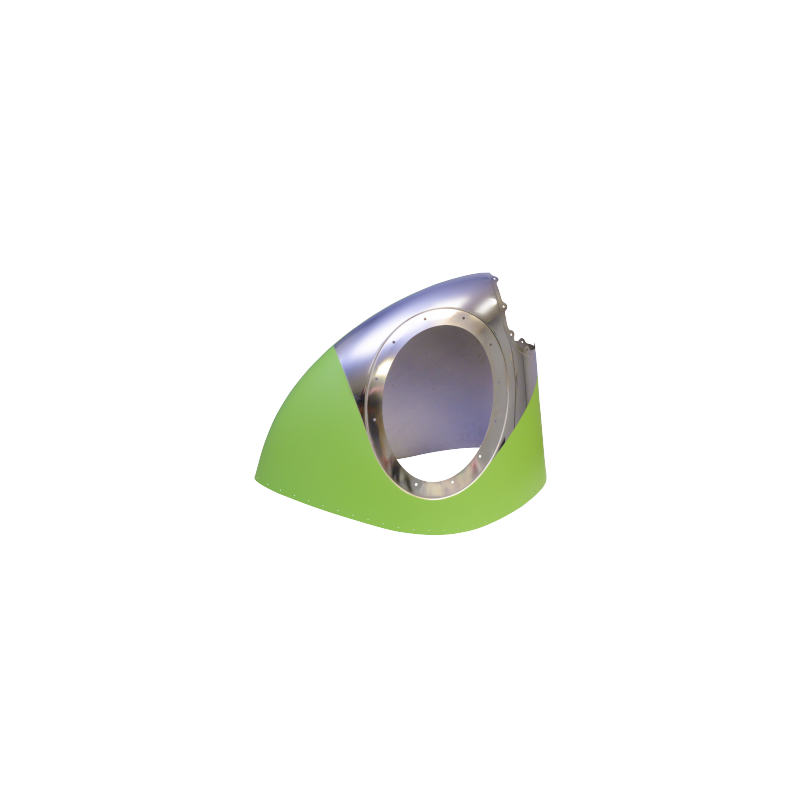

Bleed air shroud

A350

AIRBUS

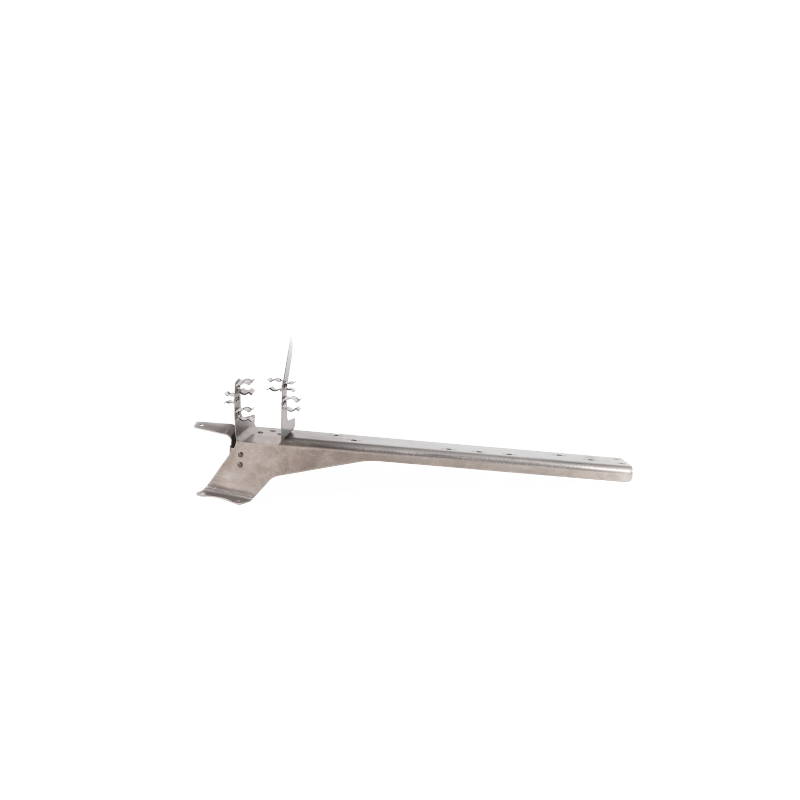

Equiped bracket

LEAP 1B

SAFRAN AIRCRAFT ENGINES

Battery support

A320

AIRBUS ATLANTIC

Cargo lining

A350

AIRBUS AEROSTRUCTURES GMBH

Main control panel

Central pedestal

A350

AIRBUS