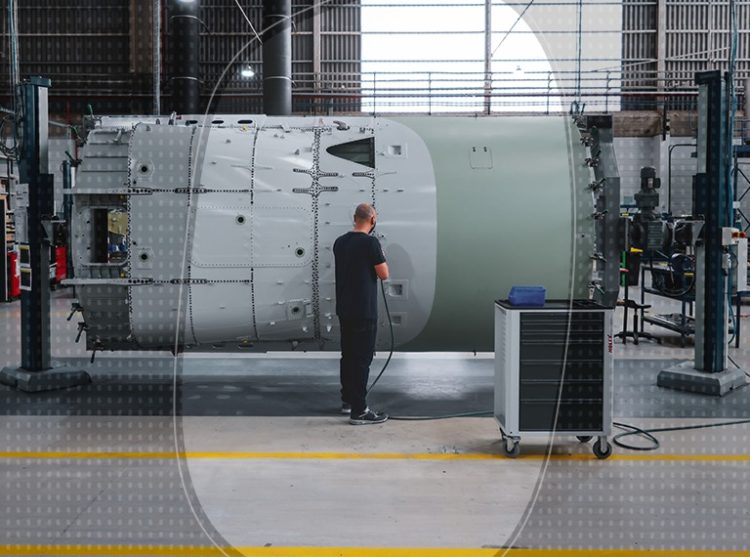

The LAUAK Group currently has 3 completely integrated production sites (1 APU in France and 2 dedicated sites in Canada and Mexico) providing the best compromise between expertise and cost.

The LAUAK Group is positioned on allfluid

transportation systems: Bleed, hydraulic, fuel, air, Fidex, etc.

We offer our customers all the processes inherent in the manufacture of pipes and their assembly or equipment:

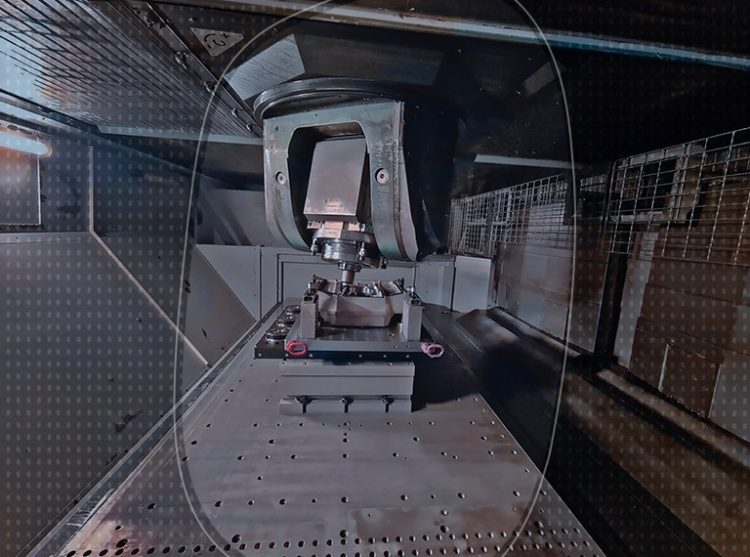

MEANS

- 10 electric bending machines

- Photometry control equipment

- Automatic and Hand TIG welding equipments

- Tube end finishing means

- Swaging equipments

- Pressure bench test

- Surface treatment and Painting lines

PROCESS

- Tube bending

- Welding

- Ducts crimping (Wiggins, Permaswage, Harrison, Deutsch)

- Non-destructive testing (dye penetrant inspection)

- Surface treatment and painting

PRODUCTS

NAI

A350

AIRBUS

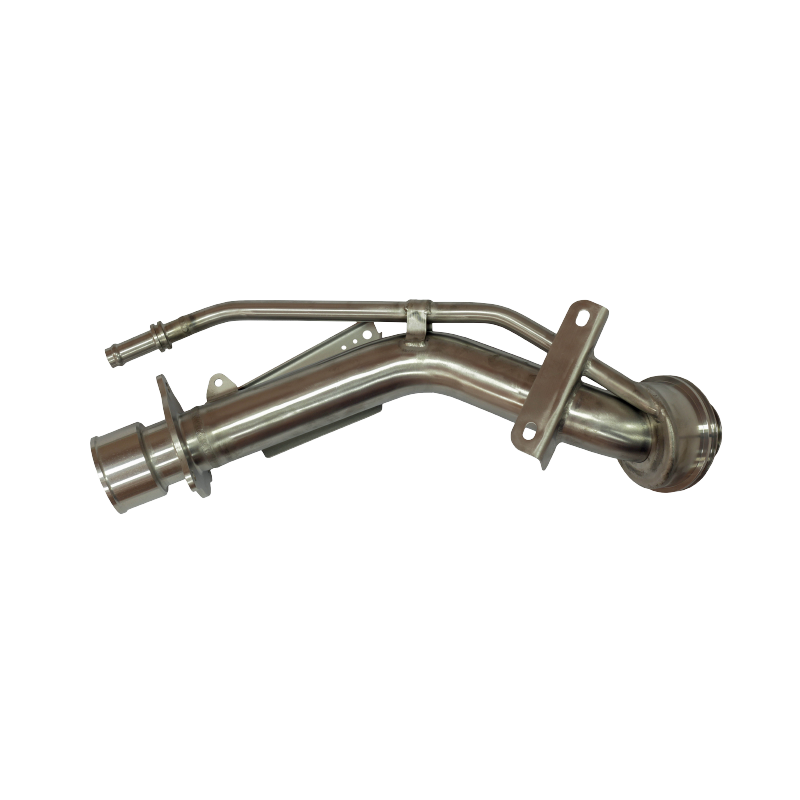

Extinction pipes assembly

A350

AIRBUS ATLANTIC

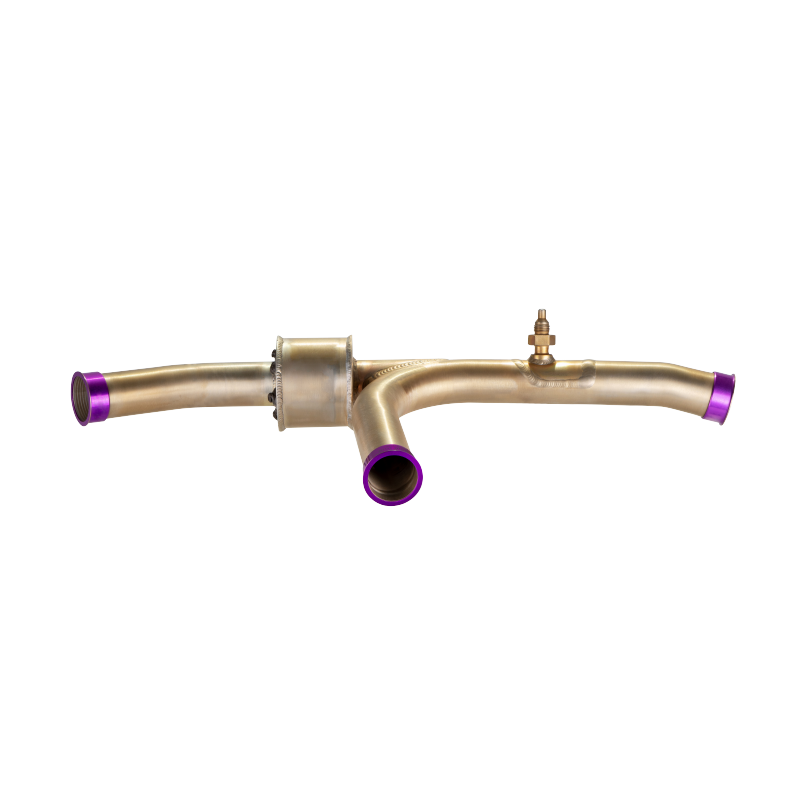

Assembled diffuser

A320

AIRBUS

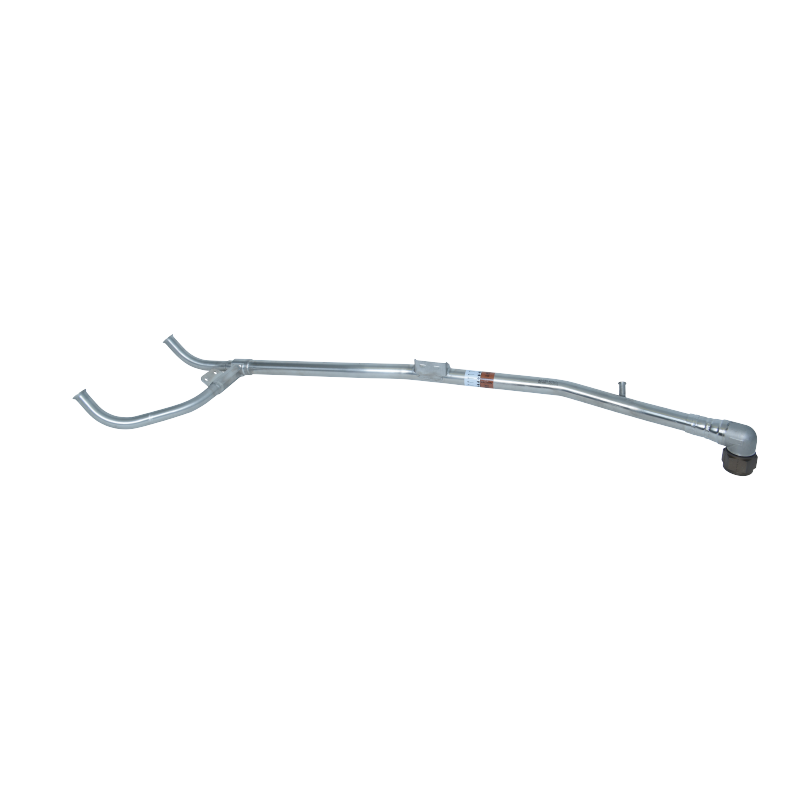

Tube assy re/defuel center wing

Challenger 300

MITSUBISHI HEAVY INDUSTRIES (MHI)

Fuel pipe

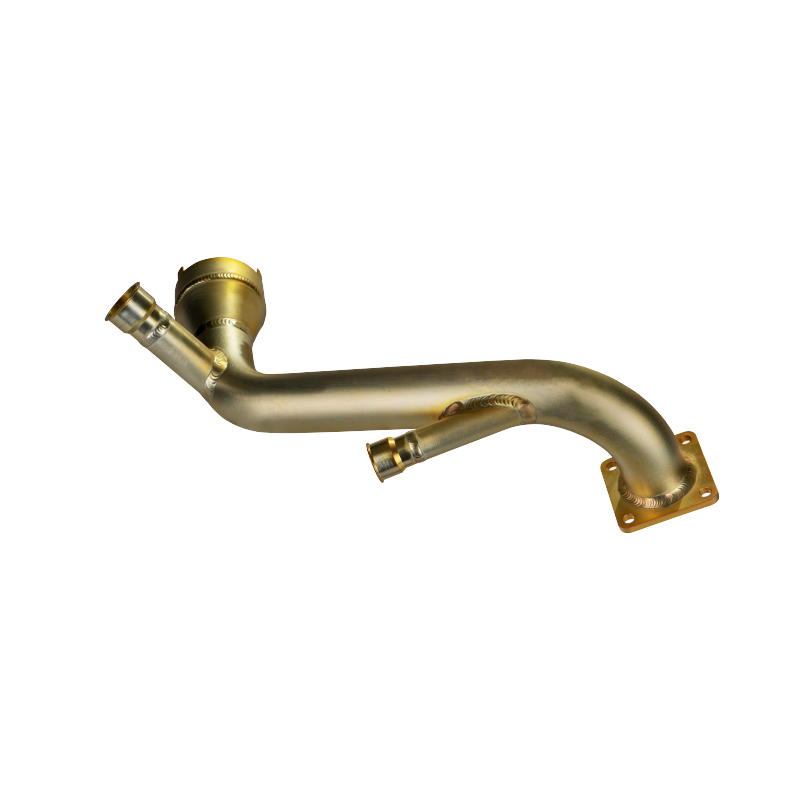

A380

AIRBUS ATLANTIC

Assy tube welding fuel system

Challenger 300

BOMBARDIER

Double piping

A320

AIRBUS

Mast assy system drain

GLOBAL 7500/8500

BOMBARDIER

Tube assy welded fuel system

CRJ 700-900

BOMBARDIER

NACA inlet assy fuel

CRJ 700-900

BOMBARDIER

Tank and fuel ejection system

CHALLENGER 350

BOMBARDIER

Assy flange tube fuel system

CHALLENGER 350

BOMBARDIER

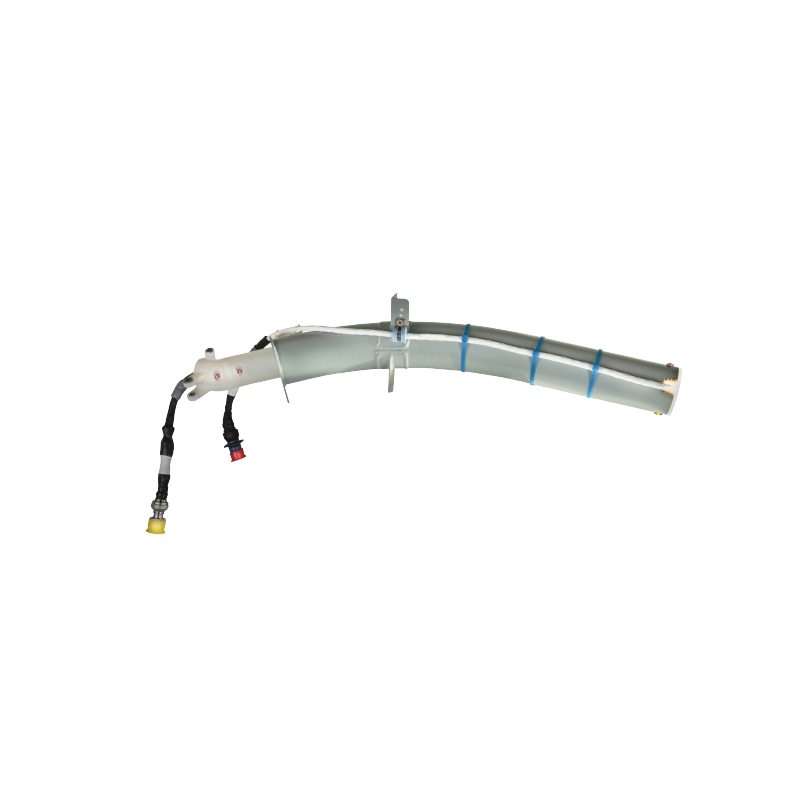

Wiring telescope assy

GLOBAL 7500/8500

BOMBARDIER

Tube assy fuel defuel refuel

CRJ 700-900

BOMBARDIER