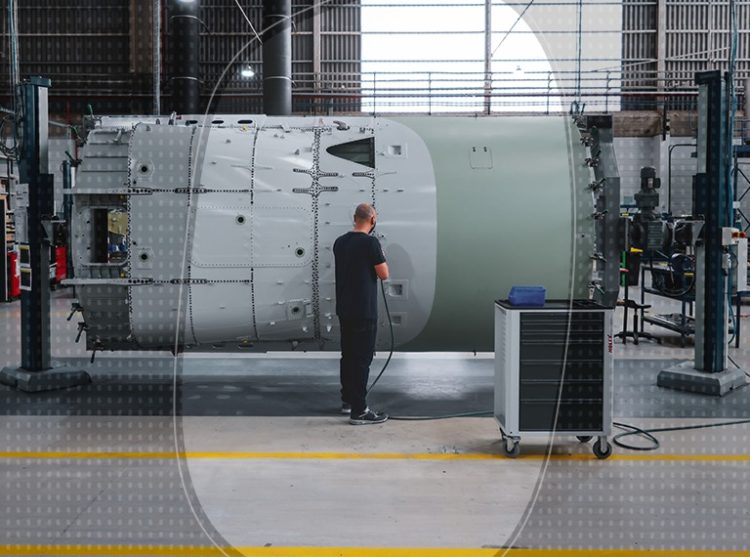

LAUAK GROUP is specialized in production of machined and welded assemblies for engine environments, particularly on its production unit in Saint-Germé. Our long time expertise is in producing complex assemblies of sheet metal, machined and welded parts, which are used on systems developed for helicopter engines or aircraft engines.

MEANS

- 2-axes laser, machining, punching and trimming machines

- 5-axes laser, machining trimming machines

- Double and Triple-action stamping presses

- TIG, MIG, Laser, Seam, Spot welding stations

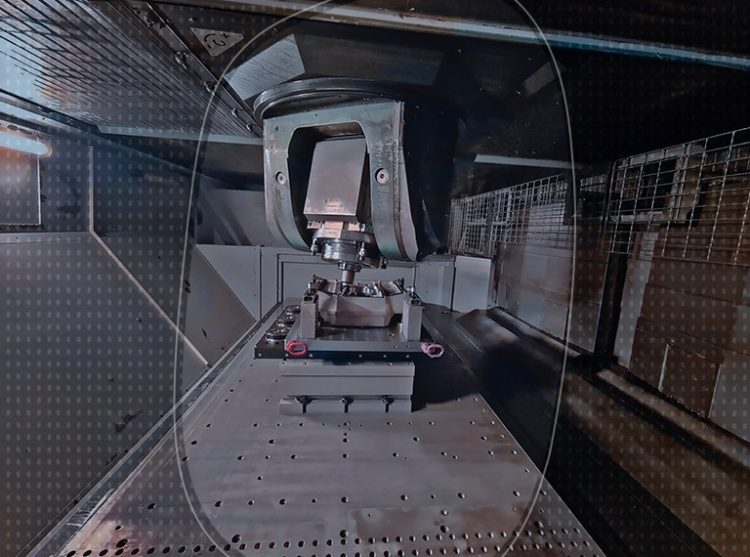

- Combined Lathe-Milling centers (horizontal and vertical, 5-axes)

- Milling centers 5-axes

- Automatized digital and analog radiography cabins

- Penetrant testing lines

- Surface treatment lines

- Paint cabins

- Welding training center, managed byLauak experts certified «International Welder Engineer and Inspector »

PROCESS

- Laser trimming and drilling

- Heat treatment

- Cold forming

- Hand, automatized, orbital welding machining

- Non-Destructive Testing (fl-ray, dye penetrant inspection)

- Dimension measurement

- Surface treatment and painting

- Sub-assembling/Fastener installations

- Qualiopy training certification

PRODUCTS

Output diffuser

MAKILA 1

SAFRAN HELICOPTER ENGINES

FT distributor

ARRIEL

SAFRAN HELICOPTER ENGINES

First Stage NGV

MAKILA 1

SAFRAN HELICOPTER ENGINES

Exhaust

ARDIDEN 3

SAFRAN HELICOPTER ENGINES

Static seal

LEAP 1B

SAFRAN AIRCRAFT ENGINES

Exhaust housing

G7500

SAFRAN POWER UNITS

Engine mount

ATR42/72

AIRBUS ATLANTIC

Housing seal

LEAP 1B

SAFRAN AICRAFT ENGINES

Exhaust

F6X

SAFRAN POWER UNITS

Exhaust liner

G7500

SAFRAN POWER UNITS